In the energy, petrochemical, construction, and infrastructure industries, the requirements for safety, reliability, and cost-effectiveness of complex engineering systems are continuously increasing. The Flow Assurance Center (FAC Institute), leveraging profound engineering experience and multidisciplinary simulation capabilities, provides advanced engineering services and consulting solutions covering the full lifecycle of design, operation, diagnostics, and optimization.

🌍 Service Areas

Oil & Gas

Power & Energy

Construction & Industrial Facilities

Data Centers & Cooling Systems

Water Treatment & Process Plants

🔧 Core Technical Services

🔹 Root Cause Analysis

Using system modeling, signal monitoring, and fault tracing, we quickly identify the root causes of engineering problems and provide actionable solutions for rectification and optimization.

🔹 Reciprocating Pump Pulsation & Vibration Analysis (API 674 / API 675)

Conduct pulsation propagation and structural response analysis of pumping systems to ensure equipment stability and extend service life.

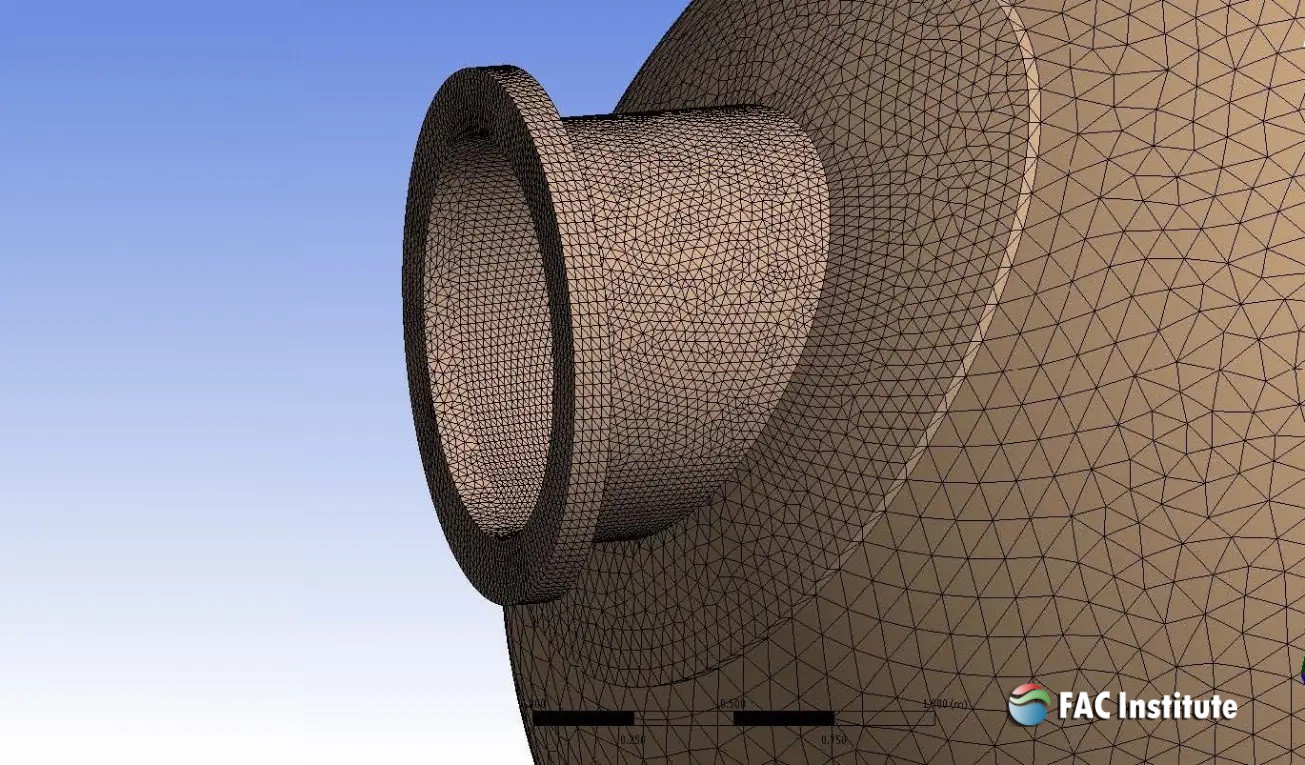

🔹 Separator Performance Evaluation

Model and optimize liquid-gas distribution, level fluctuations, and structural strength to enhance separation efficiency and reliability.

🔹 Tank Design & Structural Analysis (API 650 / API 620)

Provide mechanical and structural design to ensure long-term safety under seismic, wind, and operational loads.

🔹 Compressor Pulsation & Vibration Control (API 618)

Reduce pulsation impacts and resonance risks through fluid-structure coupling and damper optimization.

🔹 Flow-Induced Vibration & Fatigue Study (FIV / FIT / FIAV Study)

Conduct vibration and fatigue analysis on heat exchanger bundles, piping, and accessories to identify potential failure points in advance.

🔹 Fatigue & Life Assessment

Predict equipment fatigue life under cyclic loading, guiding maintenance planning and life extension.

🔹 Mixing & Reaction Performance Analysis

Investigate fluid mixing efficiency to optimize equipment design and operating conditions, improving selectivity and energy efficiency.

🔹 Heat Exchanger Maldistribution Analysis

Diagnose flow maldistribution in tube and shell sides and propose structural modifications and operational adjustments.

🔹 Flow Assurance & Pipeline Analysis

Perform multiphase flow modeling, slug tracking, wax deposition, and hydrate prediction to improve pipeline network stability.

🔹 Pipeline Stress Analysis & Support Design

Conduct stress checks and support layout in accordance with international standards to ensure safe and reliable operation under various conditions.

🔹 Dispersion & Ventilation Analysis

Simulate hazardous gas dispersion and plant ventilation to optimize emergency design and enhance safety levels.

🧠 Technical Advantages

Multidisciplinary Integration: Unified analysis of fluid, thermal, structural, and control aspects

Standards Compliance: Strict adherence to API, ASME, ISO, and other international codes

Customized Delivery: Flexible modeling and calculation schemes tailored to project requirements

Extensive Experience: Covering offshore platforms, refining plants, long-distance pipelines, and large stations

Intelligent Support: Combining digital twin and real-time monitoring to enhance operational decision-making

📦 Deliverables

Engineering Diagnostics & Optimization Reports

Dynamic/Steady-State Simulation Models

Risk Assessment & Rectification Proposals

Training & Operational Guidance Documents

Integrable Digital Tool Interfaces

📞 Contact Us

If you are facing challenges in engineering design, operational optimization, or fault diagnosis, feel free to contact the FAC Institute.

We combine scientific modeling + engineering expertise to deliver efficient, reliable, and practical technical solutions.